AlRice

Well-Known Member

- Joined

- Aug 18, 2006

- Messages

- 262

- Reaction score

- 0

<div style="margin-right: -0.5in;">Rudder pedals were my first steel projects on my

Skybolt. The reason for this was:

<div style="margin-right: -0.5in;">1. I need

practice welding.

<div style="margin-right: -0.5in;">2. If I ruined

a part, I wasn't out a lot of money or time.

<div style="margin-right: -0.5in;">3. The parts

would be ready when I needed to weld them into the fuselage.

<div style="margin-right: -0.5in;">4. They

wouldn't take up a lot of storage space.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

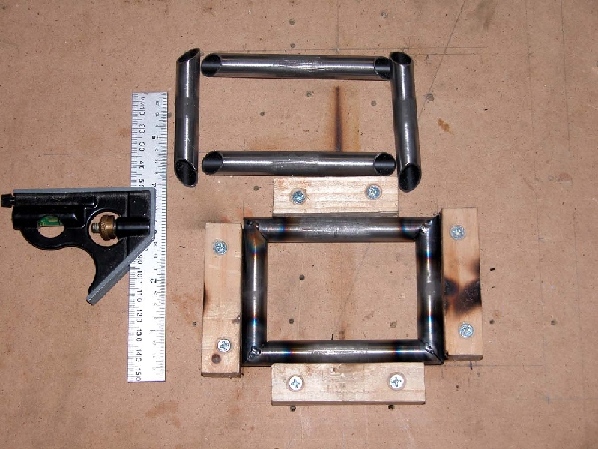

I made the easiest part first, the passenger brake

pedal. I rough mitered them a little

bigger than the dimensions then trued them up on my 12" disc sander. I jigged them on the table for fitting and

welding.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

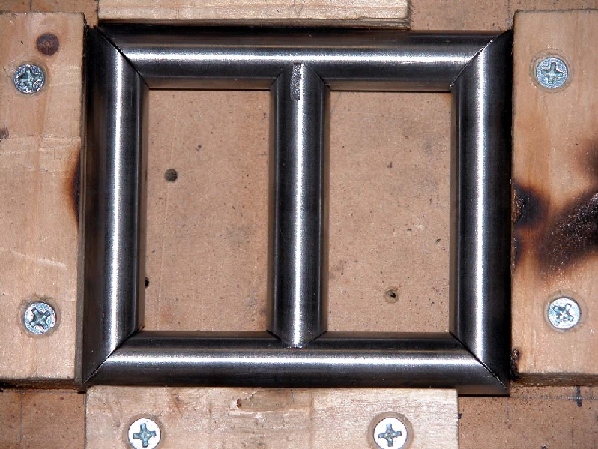

The pilot brake pedals are the same as the passenger

pedals except for the center tube which gets a brake arm welded to it. The center tube was notched on my tubing

notcher but could easily be done on the bench grinder. Do not weld the axle tabs on the brake pedals

until the rudder pedal slugs are welded.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

The rudder pedal jig holds all the tubes in position

for fitting and welding. Be sure to make

a left and right jig.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

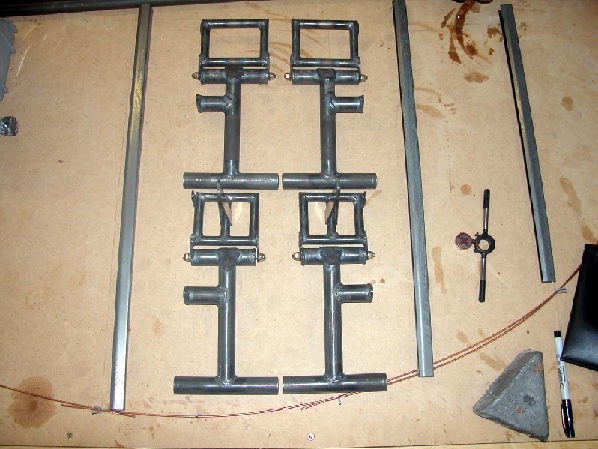

There are quite a few parts to these "easy to

build" rudder pedals. I think I

counted 45. I cut all the brackets and

slugs on my band saw then ground them to the lines with my bench grinder. I always center punch parts like these

through pin holes that I put in the patterns.

Leave the round slugs a little large and drill the center holes before

tack to the rudder pedal.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">After drilling the rudder pedal slugs for the brake

pedal axle, you need to make a jig for centering the slugs on the top rudder

pedal tube. To do this:

<div style="margin-right: -0.5in;">1. Tack weld

the basic rudder together.

<div style="margin-right: -0.5in;">2. Make up a

long 3/16 rod (about 2" longer than the top tube on the rudder pedal)

<div style="margin-right: -0.5in;">3. Cut 2

pieces of angle iron about 1.5" long.

Draw a centerline on both angle irons and then drill a 3/16" hole

7/16" up from the bottom of the angle iron.

<div style="margin-right: -0.5in;">4. Line up the

angle irons on the center line of the top rudder pedal tube so that they will

hold the slugs tight against the tube.

Screw them to the table.

<div style="margin-right: -0.5in;">5. Slide the

3/16" rod through the angle iron, slug, tube, slug and angle iron.

<div style="margin-right: -0.5in;">6. Tack weld

the slugs in place.

<div style="margin-right: -0.5in;">

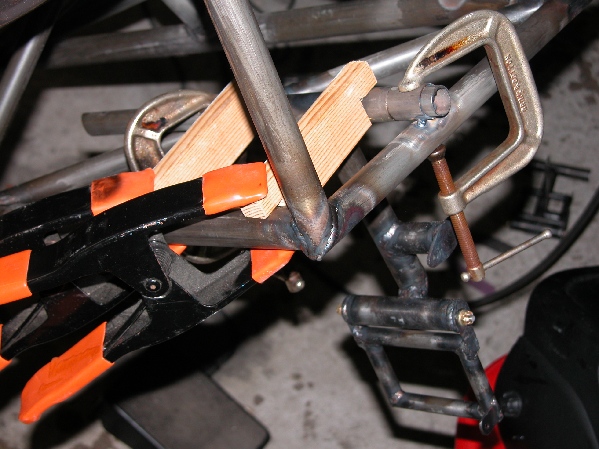

<div style="margin-right: -0.5in;">The next step is to align the brake pedal to the

rudder pedal and weld the axle tabs on the brake pedals. To do this:

<div style="margin-right: -0.5in;">1. Cut a wood

strip spacer to place between the rudder and brake pedal.

<div style="margin-right: -0.5in;">2. Align and

shim up the rudder pedal 3/16" to align the centerlines of both pedals.

<div style="margin-right: -0.5in;">3. Clamp the

brake pedal in place.

<div style="margin-right: -0.5in;">4. Make the

brake pedal axle tabs and drill them for the axle.

<div style="margin-right: -0.5in;">5. Thread the

3/16" brake axle rod according to the plans.

<div style="margin-right: -0.5in;">6. Slide the

3/16" axle through the first tab, a washer, then through the rudder pedal

tube, the second washer, and finally through the second axle tab.

<div style="margin-right: -76.5pt;">7. Snug the

axle nuts and level and align the axle tabs to the brake pedal and tack weld.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

Once the brake pedals are hinged, weld on the

remaining brackets.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

These are the completed rudder pedals.

<div style="margin-right: -0.5in;">

<div style="margin-right: -0.5in;">

This is the simple jig that I used to install the

front rudder pedals in the fuselage. It

consists of 2 - 1x2 sticks that are notched to the correct length. Use the same technique for the rear rudder

pedals. Helpful hint: Don't install the rudder pedals until you

install the seats and can actually sit in the cockpit and locate the pedals to

fit you.