Glas467

Member

- Joined

- Feb 4, 2012

- Messages

- 24

- Reaction score

- 1

This is the 4th in a series of posts about the VisionMicrosystems (VMS) VM1000 and EPI-800 engine management systems. As a reminder,Im not a FAA certified avionics technician, just an avid experimental aircraftenthusiast and EAA member passing along what Ive learned to the communitythats given so much to me. This post will cover the different versions and evolutionof the VMS product line and provide some tips for keeping each system healthyand reliable.

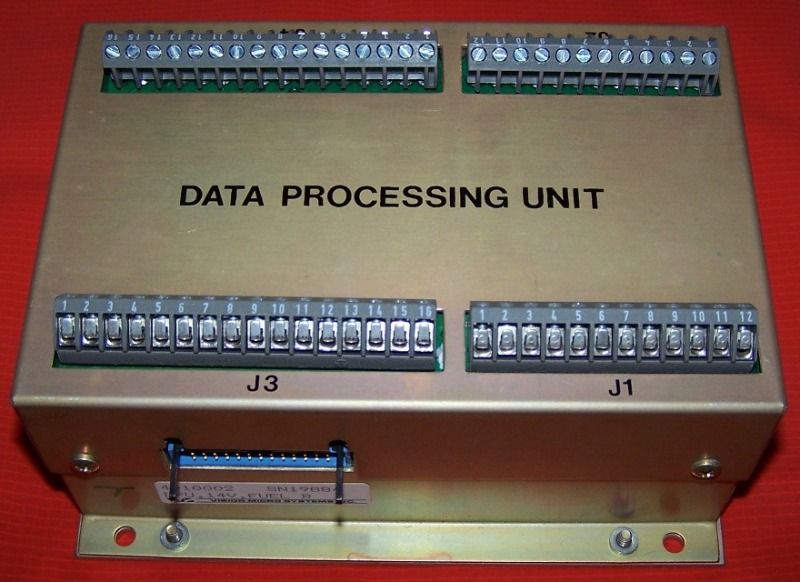

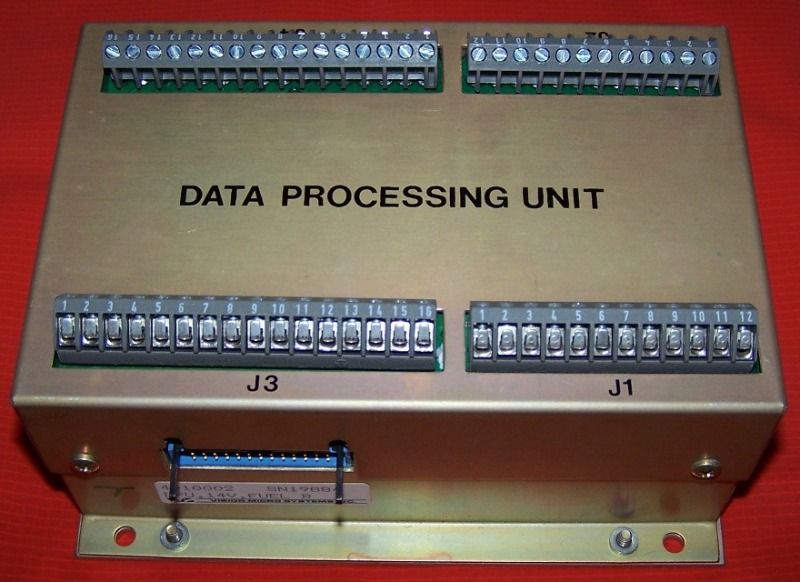

The first generation VMS system was the EPI-800 with a 1987copyright date. The data processing unit(DPU) was a screw terminal type that was the blueprint for all subsequent DPUsuntil 2001 (see pic #1). The first generation DPU had a number of limitationsall addressed in later versions. One of the most important aspects of the firstgen DPU was that it was not easy to repair because the digital and analog PCboards were hard soldered together via a set of central connection pins inthe middle of the DPU case; separating the two boards requires tedious desolderingof the central pins. Also in the first gen DPUs, there are no jumpers.Junctions are hard jumpered via soldered link so changing such parameters aspulse count for magneto vs. electronic ignition RPM sensing is difficult atbest. First gen DPUs are generally plagued by delamination issues most commonlyon the analog board but can also be found on the digital assembly as well. Youcan easily identify a first generation DPU by removing the analog board cover(cover with the cutouts for the screw terminals) and look at the pins runningfrom the board into the DPU center. Ifthese pins are flat and covered with what looks like opaque tan masking tape,its a first gen. Dont despair if you have a first gen, they still work finebut may require more labor to repair than later versions.

Pic #1: ScrewTerminal Type DPU

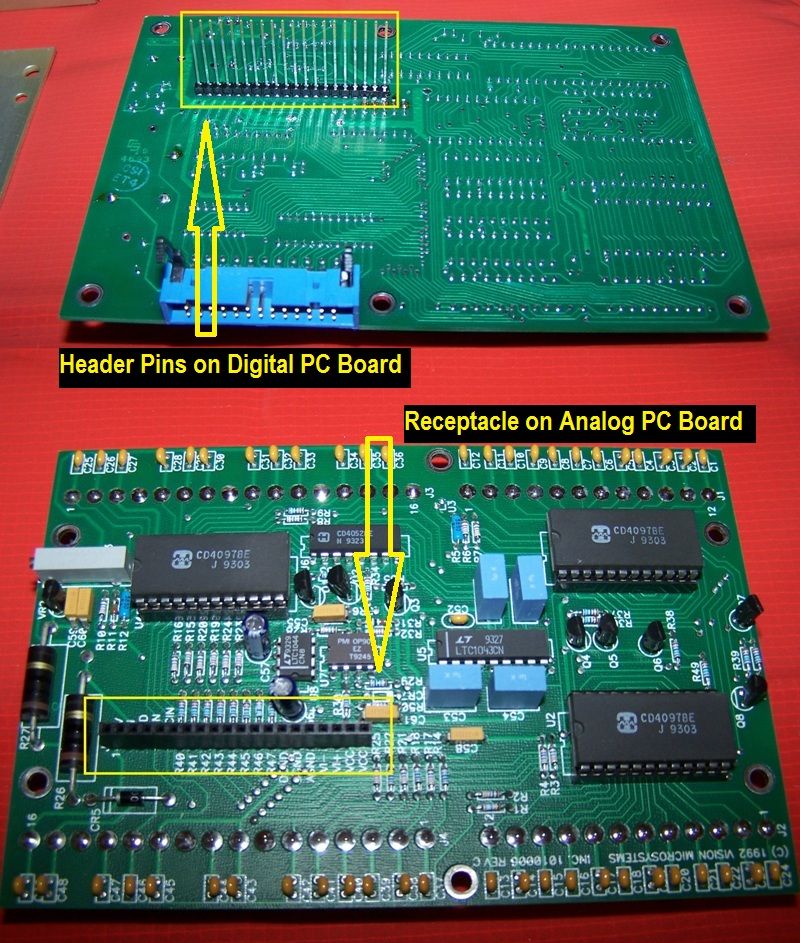

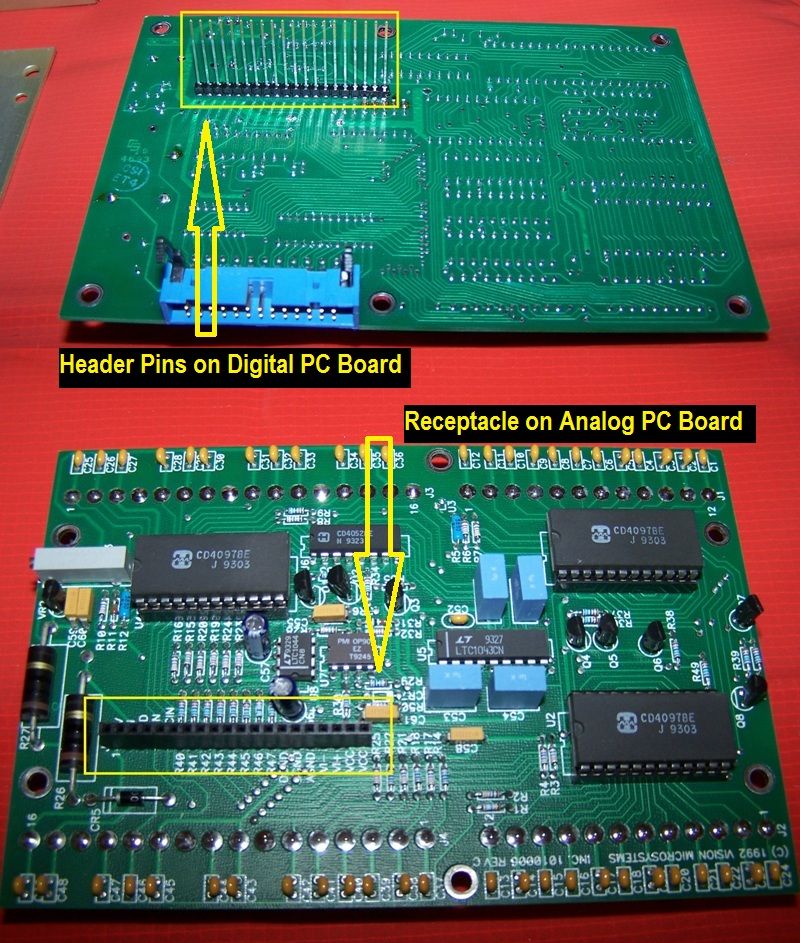

With the introduction of the VM1000 in the early 1990s, cameupgrades to the DPU and starts the second generation. First upgrade was thereplacement of hard soldered analog to digital connecting pins, with a headerpin and connector setup. Header pinswere soldered on the digital board and a receptacle assembly on the analogboard (see pic #2). Now the two boards can be easily separated for repairs. However, many of the early VM1000 DPUs stillhad hard jumpered junctions making changing options in a DPU difficult. Itwas not until the mid 90s that selectable jumpers were installed on thedigital and analog boards starting the third generation DPUs. These final modifications to the boardsbecame the standard configuration until the next major changes in 2001. These 3rd gen boards areidentified by © 1992 REV D on the analog board and © 1995 REV H on the digitalboard. These boards also have highquality etching so there are no issues with delamination as in the first andsome of the second generation units.

PIC #2: Header Pinand Receptacle Assembly

As owners will attest, screw terminal DPUs have theirlimitations. In a tight installation, the screw terminals can be difficult toproperly torque. Wires have a tendency to loosen or break at the terminals andit is easy to insert the wires too far and clamp down on the insulator insteadof the conductor resulting in an intermittent connection and a frustrating timetroubleshooting an indication problem. But with knowledge of these limitations,and making the DPU and the screw terminals part of your annual conditioninspections, owners can get good service from their systems. A simple torque check using a jewelersscrewdriver and gentle tug on each connecting wire should be all thats neededto ensure a good connection.

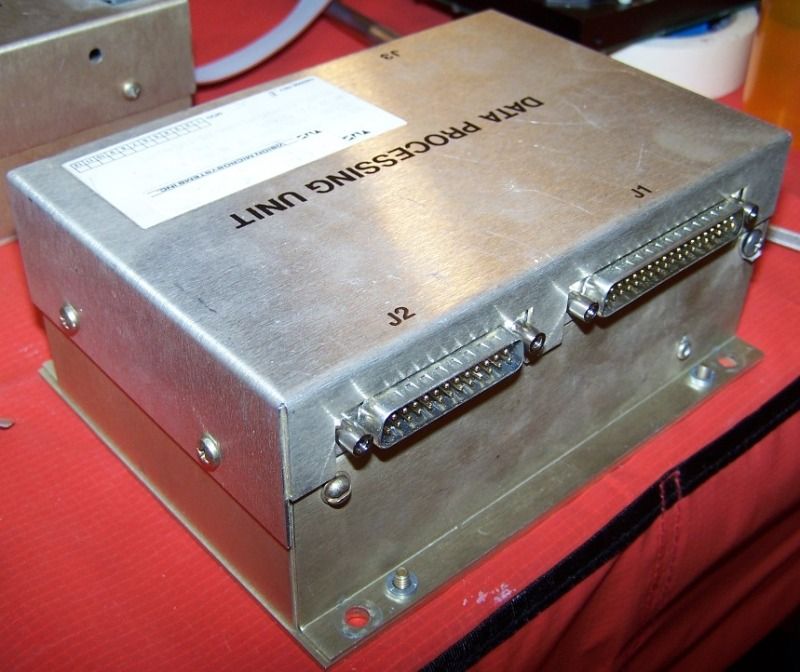

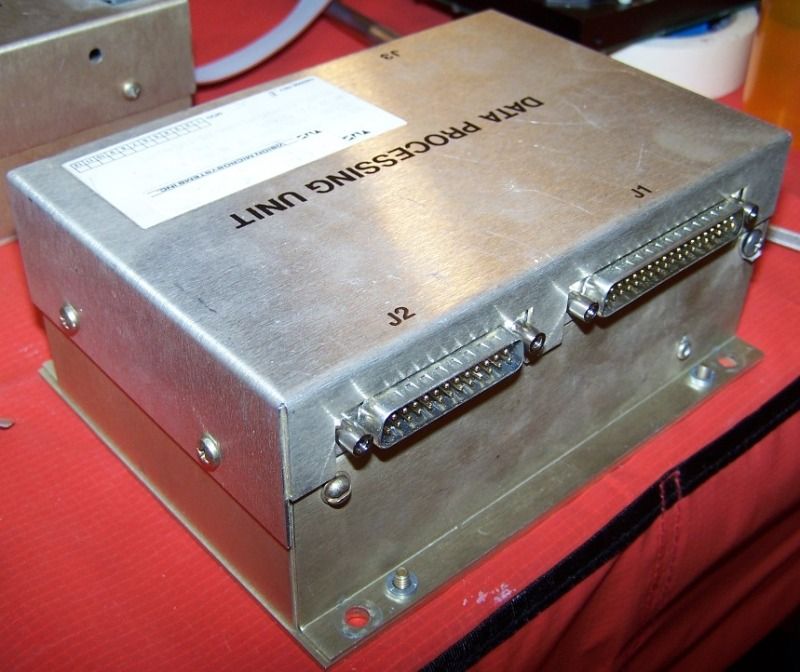

In 2001, VMS introduced a new version of most of the systemcomponents including the DPUs, displays, and sensors for both the EPI-800 andVM1000. The VM1000 also became certified under TSO-C113 and installed inseveral type certificated aircraft including the Symphony OMF-160 and LibertyXL. The great aspect of this fourth generation is all of the components arebackwards compatible with all previous systems. Most notable, on the DPU goneare the screw terminals and are replaced by two serial type connectors, asingle 25 pin RS-232 type DSUB connector which handles all the EGT and CHTsignal inputs, and a single 37 pin DSUB connector which handles power and allother sensor inputs (see pic #3). This makes for a neat, tidy, and easy toservice installation and vastly eases the work required to remove and repairthe DPU.

PIC #3: Serial Connector Type DPU

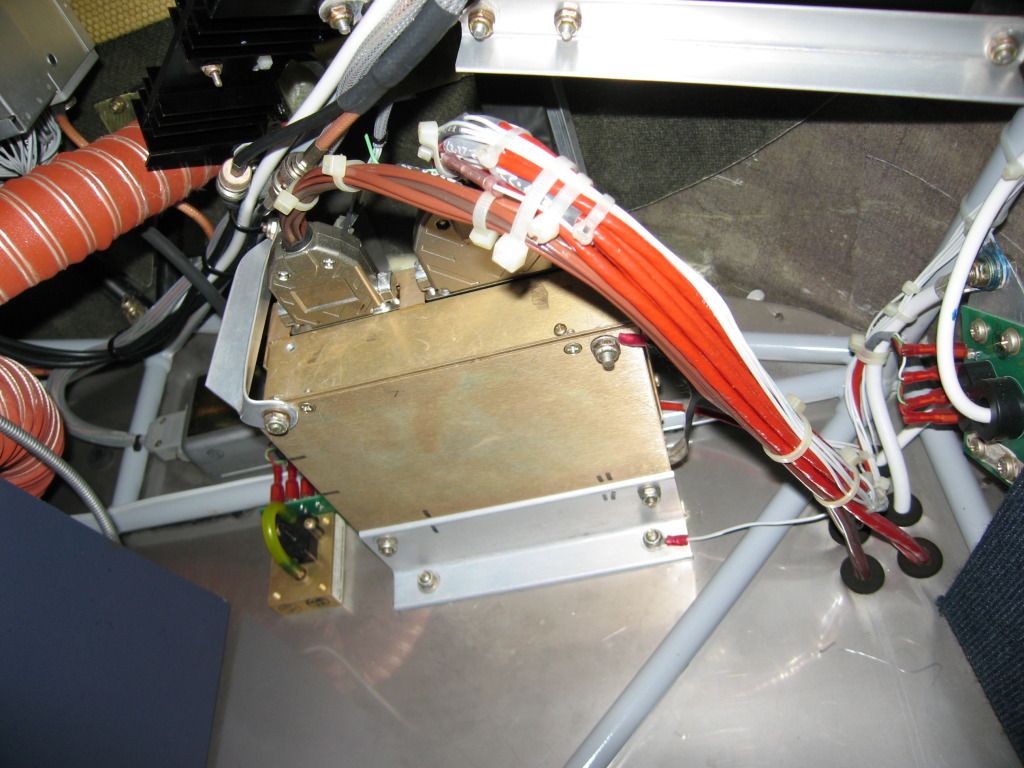

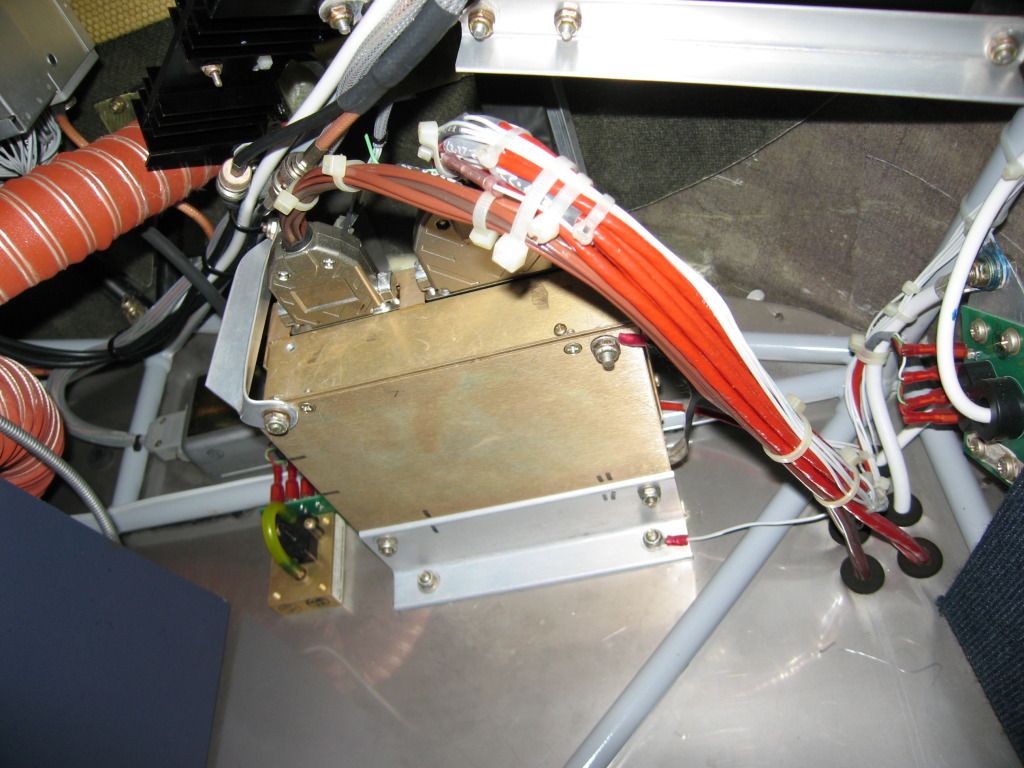

However, installation issues can compromise even this almostbullet proof connection scheme. Manyexperimental aircraft installations have the ideal geometry where connectioncables from the firewall proceed directly into the DPU, a straight connectionwhich induces no side loading on the DSUB connectors. The DPU is installed on the instrument panelwith the receptacles facing toward the firewall; these installations typicallyhave no issues with connectivity. Otherinstallations have a 90 degree geometry, cables come into the cabin then turnparallel to the firewall and connect to the DPU. If properly supported, this is also a goodconnection scheme with little problems. However, fail to properly support the cable runs, and theres apossibility of excessive vibration or resonation of the assembly whicheventually results in connections problems at the DPU and resultant displayissues in the cockpit. The worst casescenario is illustrated in the Symphony OMF-160 installation in which thesignal cables come through the firewall, make a tight radius 180 turn andconnect into the DPU with little to no support other than the DPU connectionitself (see pic #4). Symphony ownershave reported significant issues with display problems traced down toconnection issues at the DPU. Vibrationand resonation of the cable assembly can wear down the internal pins andsockets inside the DSUB connectors to the point that the contact becomesintermittent and may eventually break the solder joints of the DPUconnectors. Check your installation tomake sure your signal cables are properly supported and have an appropriateradius for any turns.

Pic #4: Serial DPU with 180 bend in Cable Connection

The 4th generation systems were also availablewith some customization not previously available. For example, one version of the VM1000included a % Power indication in place of the manifold pressure for singlelever FADEC equipped aircraft. Anotherversion was setup to output RS232 digital data to GPS units. However, the baseline EPI-800 and VM1000systems in the experimental market still seemed to dominate the bulk of salesand production with Lycoming O/IO-320/360 series setups for Glasair I &IIs, RVs, two place Lancairs, and many others; Lycoming IO-540 series forGlasair IIIs & F-1 Rockets and Continental IO- & TSIO-550s for theLancair IVs and many others.

The 4th generation represented the finaliteration of the venerable EPI-800 and VM1000 product line ... the next product, the VM1000C was essentially a clean slatedesign eventually acquired and improved by JP Instruments. If I can helpwith any Vision Microsystems issues, please feel free to email at [email protected]

Happy Flying,

Reggie

The first generation VMS system was the EPI-800 with a 1987copyright date. The data processing unit(DPU) was a screw terminal type that was the blueprint for all subsequent DPUsuntil 2001 (see pic #1). The first generation DPU had a number of limitationsall addressed in later versions. One of the most important aspects of the firstgen DPU was that it was not easy to repair because the digital and analog PCboards were hard soldered together via a set of central connection pins inthe middle of the DPU case; separating the two boards requires tedious desolderingof the central pins. Also in the first gen DPUs, there are no jumpers.Junctions are hard jumpered via soldered link so changing such parameters aspulse count for magneto vs. electronic ignition RPM sensing is difficult atbest. First gen DPUs are generally plagued by delamination issues most commonlyon the analog board but can also be found on the digital assembly as well. Youcan easily identify a first generation DPU by removing the analog board cover(cover with the cutouts for the screw terminals) and look at the pins runningfrom the board into the DPU center. Ifthese pins are flat and covered with what looks like opaque tan masking tape,its a first gen. Dont despair if you have a first gen, they still work finebut may require more labor to repair than later versions.

Pic #1: ScrewTerminal Type DPU

With the introduction of the VM1000 in the early 1990s, cameupgrades to the DPU and starts the second generation. First upgrade was thereplacement of hard soldered analog to digital connecting pins, with a headerpin and connector setup. Header pinswere soldered on the digital board and a receptacle assembly on the analogboard (see pic #2). Now the two boards can be easily separated for repairs. However, many of the early VM1000 DPUs stillhad hard jumpered junctions making changing options in a DPU difficult. Itwas not until the mid 90s that selectable jumpers were installed on thedigital and analog boards starting the third generation DPUs. These final modifications to the boardsbecame the standard configuration until the next major changes in 2001. These 3rd gen boards areidentified by © 1992 REV D on the analog board and © 1995 REV H on the digitalboard. These boards also have highquality etching so there are no issues with delamination as in the first andsome of the second generation units.

PIC #2: Header Pinand Receptacle Assembly

As owners will attest, screw terminal DPUs have theirlimitations. In a tight installation, the screw terminals can be difficult toproperly torque. Wires have a tendency to loosen or break at the terminals andit is easy to insert the wires too far and clamp down on the insulator insteadof the conductor resulting in an intermittent connection and a frustrating timetroubleshooting an indication problem. But with knowledge of these limitations,and making the DPU and the screw terminals part of your annual conditioninspections, owners can get good service from their systems. A simple torque check using a jewelersscrewdriver and gentle tug on each connecting wire should be all thats neededto ensure a good connection.

In 2001, VMS introduced a new version of most of the systemcomponents including the DPUs, displays, and sensors for both the EPI-800 andVM1000. The VM1000 also became certified under TSO-C113 and installed inseveral type certificated aircraft including the Symphony OMF-160 and LibertyXL. The great aspect of this fourth generation is all of the components arebackwards compatible with all previous systems. Most notable, on the DPU goneare the screw terminals and are replaced by two serial type connectors, asingle 25 pin RS-232 type DSUB connector which handles all the EGT and CHTsignal inputs, and a single 37 pin DSUB connector which handles power and allother sensor inputs (see pic #3). This makes for a neat, tidy, and easy toservice installation and vastly eases the work required to remove and repairthe DPU.

PIC #3: Serial Connector Type DPU

However, installation issues can compromise even this almostbullet proof connection scheme. Manyexperimental aircraft installations have the ideal geometry where connectioncables from the firewall proceed directly into the DPU, a straight connectionwhich induces no side loading on the DSUB connectors. The DPU is installed on the instrument panelwith the receptacles facing toward the firewall; these installations typicallyhave no issues with connectivity. Otherinstallations have a 90 degree geometry, cables come into the cabin then turnparallel to the firewall and connect to the DPU. If properly supported, this is also a goodconnection scheme with little problems. However, fail to properly support the cable runs, and theres apossibility of excessive vibration or resonation of the assembly whicheventually results in connections problems at the DPU and resultant displayissues in the cockpit. The worst casescenario is illustrated in the Symphony OMF-160 installation in which thesignal cables come through the firewall, make a tight radius 180 turn andconnect into the DPU with little to no support other than the DPU connectionitself (see pic #4). Symphony ownershave reported significant issues with display problems traced down toconnection issues at the DPU. Vibrationand resonation of the cable assembly can wear down the internal pins andsockets inside the DSUB connectors to the point that the contact becomesintermittent and may eventually break the solder joints of the DPUconnectors. Check your installation tomake sure your signal cables are properly supported and have an appropriateradius for any turns.

Pic #4: Serial DPU with 180 bend in Cable Connection

The 4th generation systems were also availablewith some customization not previously available. For example, one version of the VM1000included a % Power indication in place of the manifold pressure for singlelever FADEC equipped aircraft. Anotherversion was setup to output RS232 digital data to GPS units. However, the baseline EPI-800 and VM1000systems in the experimental market still seemed to dominate the bulk of salesand production with Lycoming O/IO-320/360 series setups for Glasair I &IIs, RVs, two place Lancairs, and many others; Lycoming IO-540 series forGlasair IIIs & F-1 Rockets and Continental IO- & TSIO-550s for theLancair IVs and many others.

The 4th generation represented the finaliteration of the venerable EPI-800 and VM1000 product line ... the next product, the VM1000C was essentially a clean slatedesign eventually acquired and improved by JP Instruments. If I can helpwith any Vision Microsystems issues, please feel free to email at [email protected]

Happy Flying,

Reggie