Back in late December, I started building a Pitts S1. I began with Aviat plans, and originally planned on building a completely plans based S1S, before jmorgan put up a Wolf wing rib kit in the classifieds here, which I bought from him and began work on earlier this month. I'm now leaning towards a Wolf tail to go with the wings, but keeping an upright seat back and plans style gear.

The fuselage tubing came from VR3, which has been a huge time saver. I actually built a set of S1S ribs before moving over the the Wolf ribs, which you can see in the photos below.

Anyhow, here's a progression of how things have gone for the last few months, this might be interesting, or it might be a lot like looking at someone else's vacation slides:

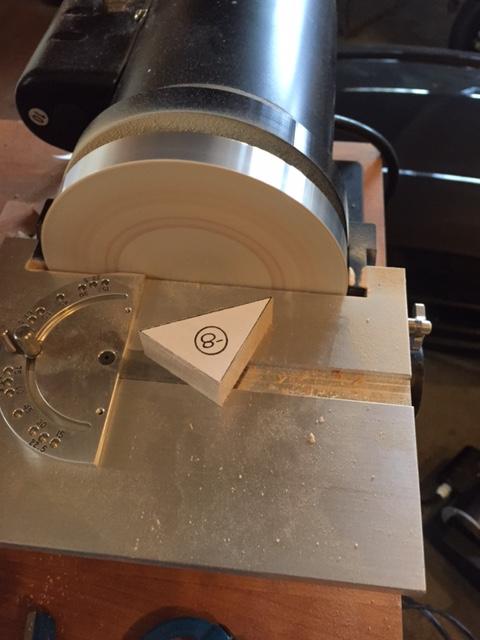

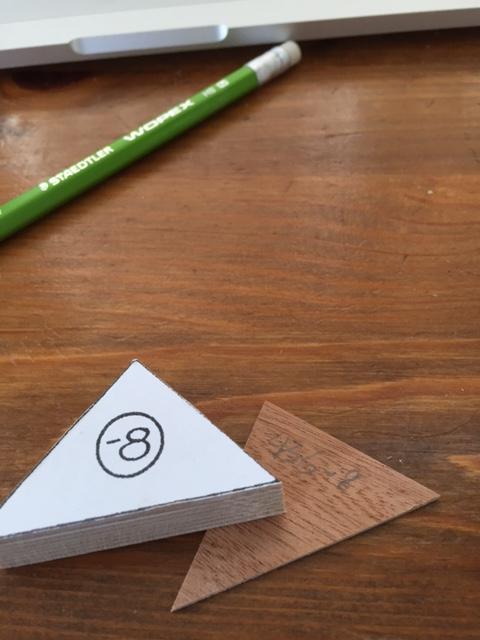

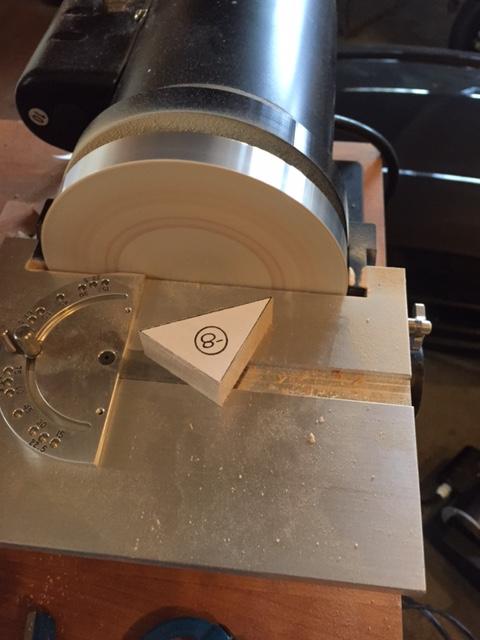

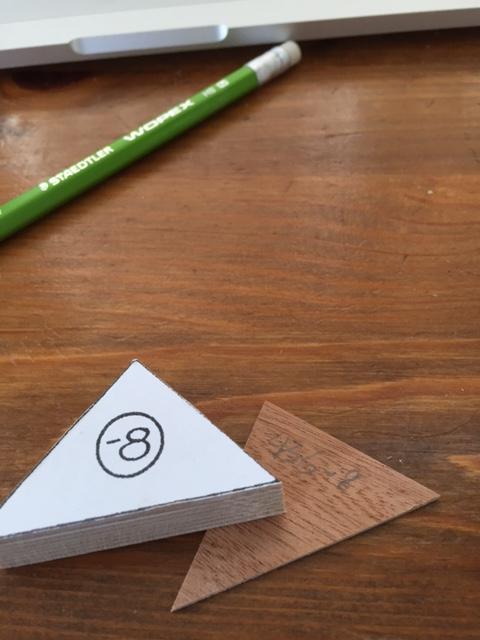

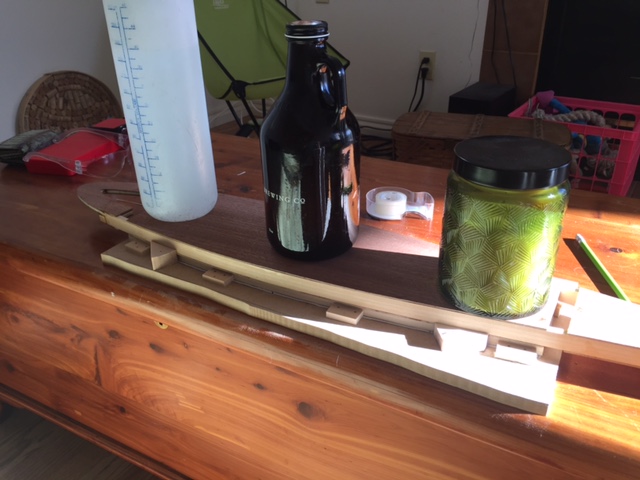

Cutting gussets for the -S wing ribs:

Routing nose blocks for the -S ribs:

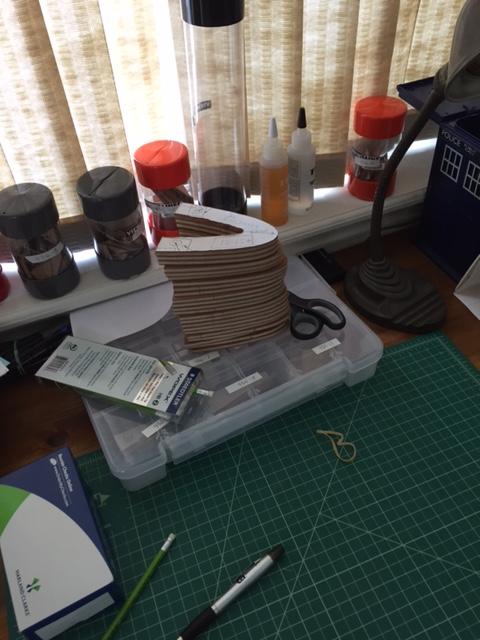

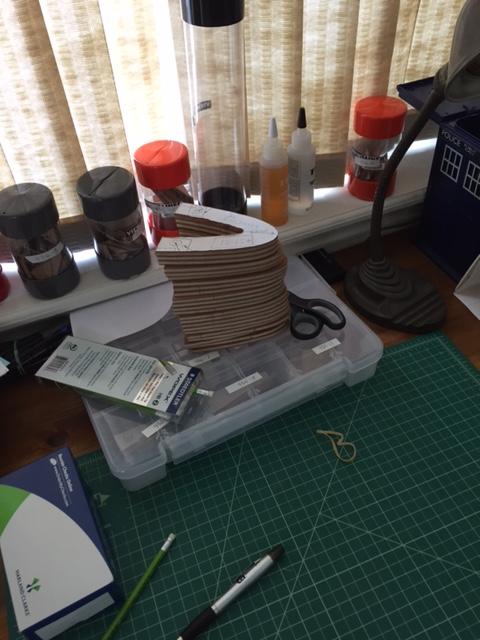

Gluing up -S ribs on a nail based jig:

A jig for the center ribs, these were tricky because they have an inner lip glued to one side of the rib:

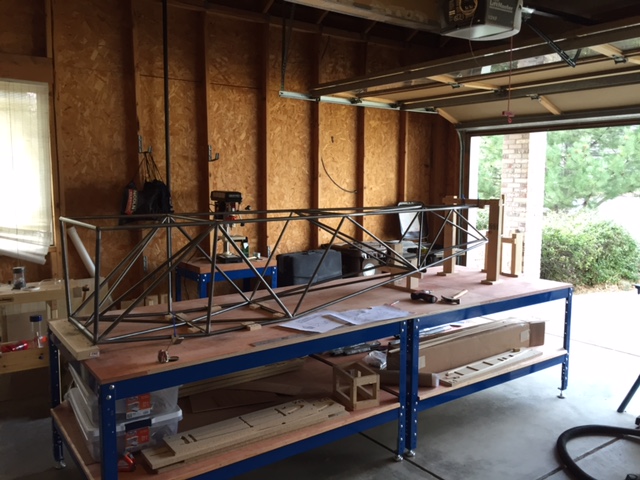

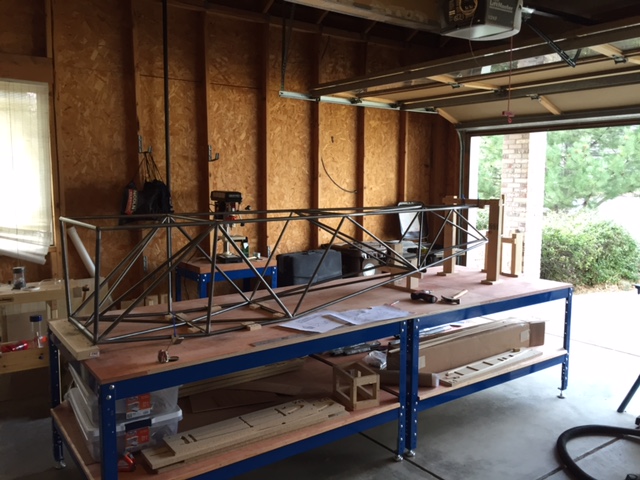

And the fun part, building the fuselage:

(this is the first "sitting in it" photo)

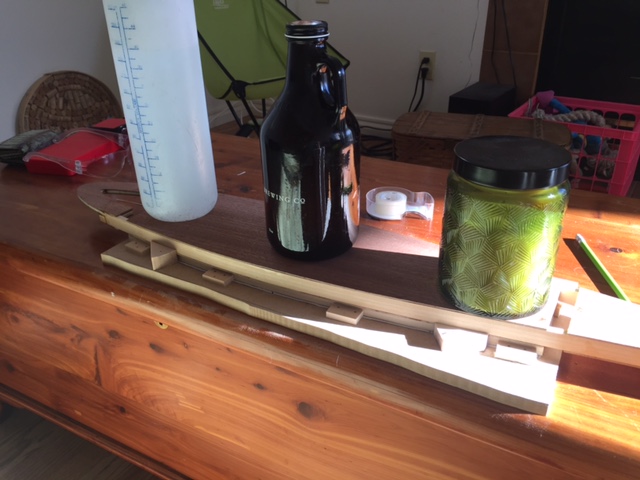

Jigging the tail:

and the cabane struts, VR3 doesn't cope the cabane struts, they just saw cut to length. The jigging and coping is taking a lot of work. This is the moment when I really realized how much time ordering coped tubing has saved.

What's next? The main fuselage structure is mostly finish welded, but the tail, rear diagonals, seat, and cabane struts are all just tacked right now. I need to finish the cabane construction, finish weld what's left, put in the horizontal tail bracing, build landing gear, and about one million other fuselage steps. Luckily, the measurements from the tailpost to the firewall corners only differ by 3/64", or something like that, so everything is pretty straight

The Wolf rib kit is nearing completion (I'm at 39 out of 40 ribs, and am about to begin on aileron ribs), and Chris Murley should have some spars for it soon.

This is about 300 hours worth of work, although I've had help for a lot of it, and there are two different full sets of wing ribs in there, so I don't think my hour count is useful to anyone else. I did an EAA inspection around 150 hours, and should really do another one soon.

The fuselage tubing came from VR3, which has been a huge time saver. I actually built a set of S1S ribs before moving over the the Wolf ribs, which you can see in the photos below.

Anyhow, here's a progression of how things have gone for the last few months, this might be interesting, or it might be a lot like looking at someone else's vacation slides:

Cutting gussets for the -S wing ribs:

Routing nose blocks for the -S ribs:

Gluing up -S ribs on a nail based jig:

A jig for the center ribs, these were tricky because they have an inner lip glued to one side of the rib:

And the fun part, building the fuselage:

(this is the first "sitting in it" photo)

Jigging the tail:

and the cabane struts, VR3 doesn't cope the cabane struts, they just saw cut to length. The jigging and coping is taking a lot of work. This is the moment when I really realized how much time ordering coped tubing has saved.

What's next? The main fuselage structure is mostly finish welded, but the tail, rear diagonals, seat, and cabane struts are all just tacked right now. I need to finish the cabane construction, finish weld what's left, put in the horizontal tail bracing, build landing gear, and about one million other fuselage steps. Luckily, the measurements from the tailpost to the firewall corners only differ by 3/64", or something like that, so everything is pretty straight

The Wolf rib kit is nearing completion (I'm at 39 out of 40 ribs, and am about to begin on aileron ribs), and Chris Murley should have some spars for it soon.

This is about 300 hours worth of work, although I've had help for a lot of it, and there are two different full sets of wing ribs in there, so I don't think my hour count is useful to anyone else. I did an EAA inspection around 150 hours, and should really do another one soon.