- Joined

- Aug 5, 2008

- Messages

- 313

- Reaction score

- 103

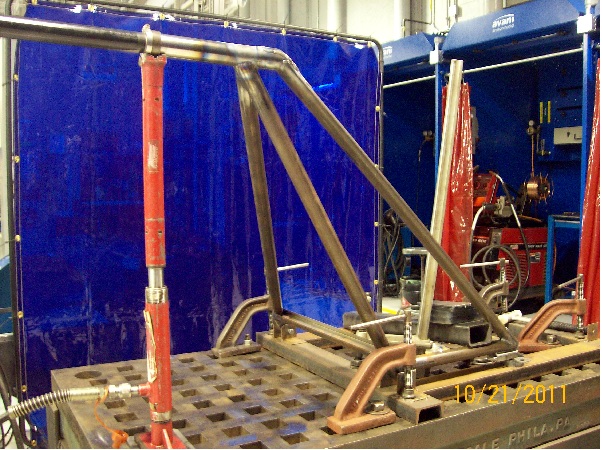

Here's the update I promised in my June

post on building the MLG. There's a very interesting current thread started by

PabloJ3 on the Pitts side of the house regarding camber and toe-in. First

problem was what's the best angles and then how to make the adjustments once

the welding is finished. Best information I found was from Kevin Kimball,

posted Dec 10, 2009 recommending 3 to 5 degrees positive camber and zero toe-in

with tail wheel about 15 inches off the ground. Thanks, Kevin. The Decathalon

manual specifies zero to one degree of toe-in. My hangar mate has a Sonex--.7

degrees of toe-in. Of course 3 to 5 degrees depends on the weight of the

aircraft and the flexibility of the gear structure. Honestly, this sounded like

a lot of camber. After the welding was finished this summer, I had about 1/2

degree positive camber and very slight toe-out. I turned the fuselage up side

down, supported it firmly, and loaded each axel with about 200 pounds of steel.

I measured the deflections at zero, 100 pounds and 200 pounds and plotted the

results. When extrapolated to the 600 to 800 pound range, my test indicated 3

degrees of camber would be right for my project. Some additional calculations

showed +3 deg of camber and zero toe-in in the level flight attitude would

translate into +3 deg and about 1/2 degree of toe-in in the three point

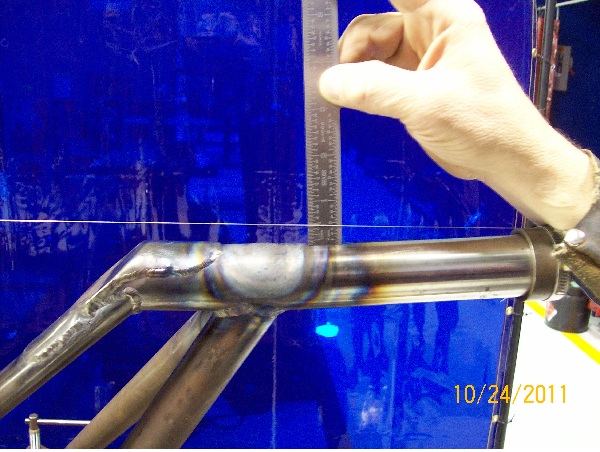

attitude. I elected to bend the axels by heatingafter applying

pressure with a port-a-power. About 5/16" cold deflection with the port-a-power

resulted in about 1/8 inch of movement when the axel was heated to a dull red

circle about 1-1/2 diameter wrapping about 180 degrees around the axel. The

heating was done directly over the axel cluster. I'm posting a few pictures to

show the set up. If you look at the top of the axels (as seen in the last picture)

you can see the bulge produced by shrinking the metal. I stretched a wire

between the axel tips and measured deflection 7 inches inboard from each tip to

gauge the camber. Over seven inches of axel length, a 3/8" deflection gives

very close to three degrees. In the process of changing the camber, the toe-in

(level flight attitude) came back to zero degrees within my ability to measure.

I waited to mount the brake backing plates until this operation was complete. I

also turned down a piece of schedule 40 black pipe and telescoped it into the

axel during heating and bending to keep the axel round. When I get into the air

my tire wear and ground handling should give me some feed back on these settings. My helper Dave is posing with the torch in the first picture. Hope this is helpful. Questions welcome. Ed Td