AlRice

Well-Known Member

- Joined

- Aug 18, 2006

- Messages

- 262

- Reaction score

- 0

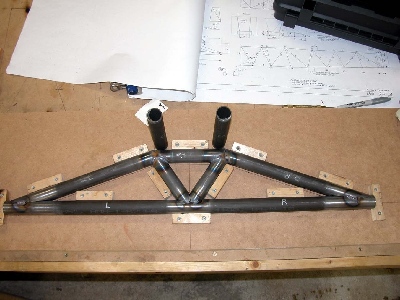

<div style="text-align: center;" align="center">Landing Gear Truss Fabrication

<div style="">

<div style="">Note: I recommend fabricating the landing gear truss before starting on the fuselage so that it can be used to properly

space the bottom longerons when assembling the 2 fuse sides to each other.

<div style="">

<div style="">Step

1: Draw the truss layout on a board cut

about 4" longer than the finished truss.

<div style="">Step

2: Screw jig blocks to the board to hold

all the tubes in position.

<div style="">Step

3: Cut the bottom tube to length, making

it a little longer than needed.

<div style="">

Step

4: Cut the upper right and left tubes

about 1â longer than the final dimension.

<div style="">Step

5: Using a bench grinder, fit the upper

right and left tubes to the bottom tube.

<div style="">Step

6: Miter the upper ends of the upper

right and left tubes. Use a square to

ensure that the upper and lower sides of the tube ends are square with the jig

board. A 12â disc sander makes this job

easy.

<div style="">Step

7: Cut the top center tube a little

longer than needed and miter the ends to fit the right and left tubes.

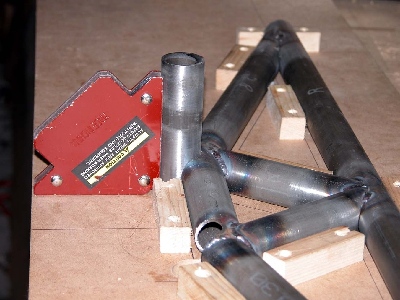

<div style="">Step

8: Using a tubing notcher and/or bench

grinder, fit the 2 âVâ tubes.

<div style="">Step

9: Tack everything weld together.

<div style="">Step

10: Take the truss out of the jig and on

the jig board, mark the longeron intersections so that the bottom of the

longerons will be flush with the bottom of the truss tube.

<div style="">Step

11: With a proper size holesaw, cut

through the jig board at the longeron and bungee tube intersections.

<div style="">

Step

12: Put the truss back in the jig and

place the assembly upside down on your drill press.

<div style="">Step

13: Take the pilot drill out of the

holesaw.

<div style="">Step

14: Keeping the jig level and using the pre-sawn

holes in the jig as a guide, drill down through the truss at the 4 locations

for the longeron and bungee tubes.

<div style="">

Step

15: Cut the bungee tubes to length,

center and square them on the truss, and tack weld while the truss is still in

the jig.

<div style="">

Step

16: Remove the truss from the jig and

tack weld the 4 end plates to the bungee tubes.

<div style="">Step

17: Finish weld the assembly.

Edited by: AlRice