Flt4CancerPitts

Member

- Joined

- Jul 28, 2008

- Messages

- 6

- Reaction score

- 0

Dear Steel tube welding experts:

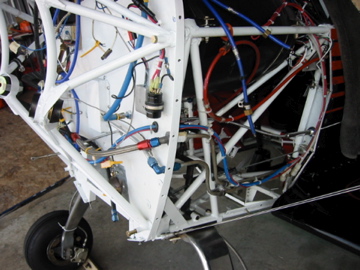

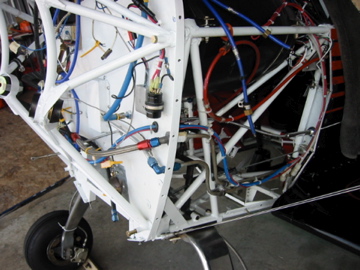

As a new user here. I own a Pitts S1-X? I guess u could call it. I am looking for expertise in the the spring gear area. Specifically I am re-welding the front of my Pitts S1 Fuselage. I am attempting to strengthen the lower longeron area to keep them from cracking. The cracks appeared at the rudder pedal pivot point on the lower left longeron.

My Pitts was rebuilt by Doug Dodge in the mid 80's. it was modified from the bungee gear to the spring gear at the time. There was a "u" channel welded to the lower longeron to create a "flat" spot for the gear to attach. The gear attach bolts are 1 3/4" inboard of the outer lower longerons. The lower longeron cracked above the gear between the two gear attach bolts.

The diagonal brace goes from the rear gear attach bolts to the upper engine attach bolt. That is, there is a sleve welded to the top portion of this diagonal that accepts the back of the upper engine mount attach bolt.

Question 1: isnt this diagonal supposed to attach to the respective upper corner cluster? Dosent any upward movement put unwanted stress on the engine attach bolt?

I am cutting the foward lower longerons off fwd of the wing attach points.

Then rosette welding sleves as per the Steen aero plans. I think the steen design for the spring gear attach area appears to be very strong. Instead of a "U" channel welded to the bottom of the longeron, it sleves a .100 tube on top of the fixed 5/8th existing tube. They then attach the gear bushings by radiusing the inner lower longeron and welds them in place.

I have installed the Grove radius plates and have flown then for a few years now. They seem to have helped a lot. However, it seems to me that the for/aft movement of the spring gear loads the longerons perpendicular to the tube.

Question 2:

is there to any need to strengthen the gear in addition to the Steen lab plan exsisting design?

Regards to al.

Greg Clauser

cancer survivor[

As a new user here. I own a Pitts S1-X? I guess u could call it. I am looking for expertise in the the spring gear area. Specifically I am re-welding the front of my Pitts S1 Fuselage. I am attempting to strengthen the lower longeron area to keep them from cracking. The cracks appeared at the rudder pedal pivot point on the lower left longeron.

My Pitts was rebuilt by Doug Dodge in the mid 80's. it was modified from the bungee gear to the spring gear at the time. There was a "u" channel welded to the lower longeron to create a "flat" spot for the gear to attach. The gear attach bolts are 1 3/4" inboard of the outer lower longerons. The lower longeron cracked above the gear between the two gear attach bolts.

The diagonal brace goes from the rear gear attach bolts to the upper engine attach bolt. That is, there is a sleve welded to the top portion of this diagonal that accepts the back of the upper engine mount attach bolt.

Question 1: isnt this diagonal supposed to attach to the respective upper corner cluster? Dosent any upward movement put unwanted stress on the engine attach bolt?

I am cutting the foward lower longerons off fwd of the wing attach points.

Then rosette welding sleves as per the Steen aero plans. I think the steen design for the spring gear attach area appears to be very strong. Instead of a "U" channel welded to the bottom of the longeron, it sleves a .100 tube on top of the fixed 5/8th existing tube. They then attach the gear bushings by radiusing the inner lower longeron and welds them in place.

I have installed the Grove radius plates and have flown then for a few years now. They seem to have helped a lot. However, it seems to me that the for/aft movement of the spring gear loads the longerons perpendicular to the tube.

Question 2:

is there to any need to strengthen the gear in addition to the Steen lab plan exsisting design?

Regards to al.

Greg Clauser

cancer survivor[